Diesel engines have long been the workhorses of the transportation and industrial sectors, known for their power and efficiency. However, they are also significant contributors to air pollution, particularly in the form of nitrogen oxides (NOx), which are harmful to both human health and the environment. As regulations have tightened globally to curb these emissions, technologies like Selective Catalytic Reduction (SCR) have become essential. Central to the effectiveness of SCR technology is AdBlue, a seemingly simple but highly effective solution.

Understanding NOx Emissions

To fully grasp the importance of AdBlue, it’s essential to understand what NOx emissions are and why they are problematic. NOx is a collective term for nitrogen oxide (NO) and nitrogen dioxide (NO2), both of which are byproducts of combustion at high temperatures, such as those found in diesel engines. When released into the atmosphere, NOx contributes to the formation of smog and acid rain, and it exacerbates respiratory issues in humans, particularly in urban areas where traffic density is high.

Reducing NOx emissions has thus become a critical objective for governments and industries alike, leading to the development of various technologies aimed at minimizing these pollutants. SCR, combined with AdBlue, is one of the most effective methods currently in use.

What is AdBlue and How Does it Work?

AdBlue, also known as Diesel Exhaust Fluid (DEF) in some regions, is a high-purity urea solution. It consists of 32.5% urea and 67.5% deionized water, a precise formulation that is both non-toxic and non-hazardous. The science behind AdBlue lies in its ability to reduce NOx emissions through a chemical reaction that occurs within the SCR system of a diesel engine.

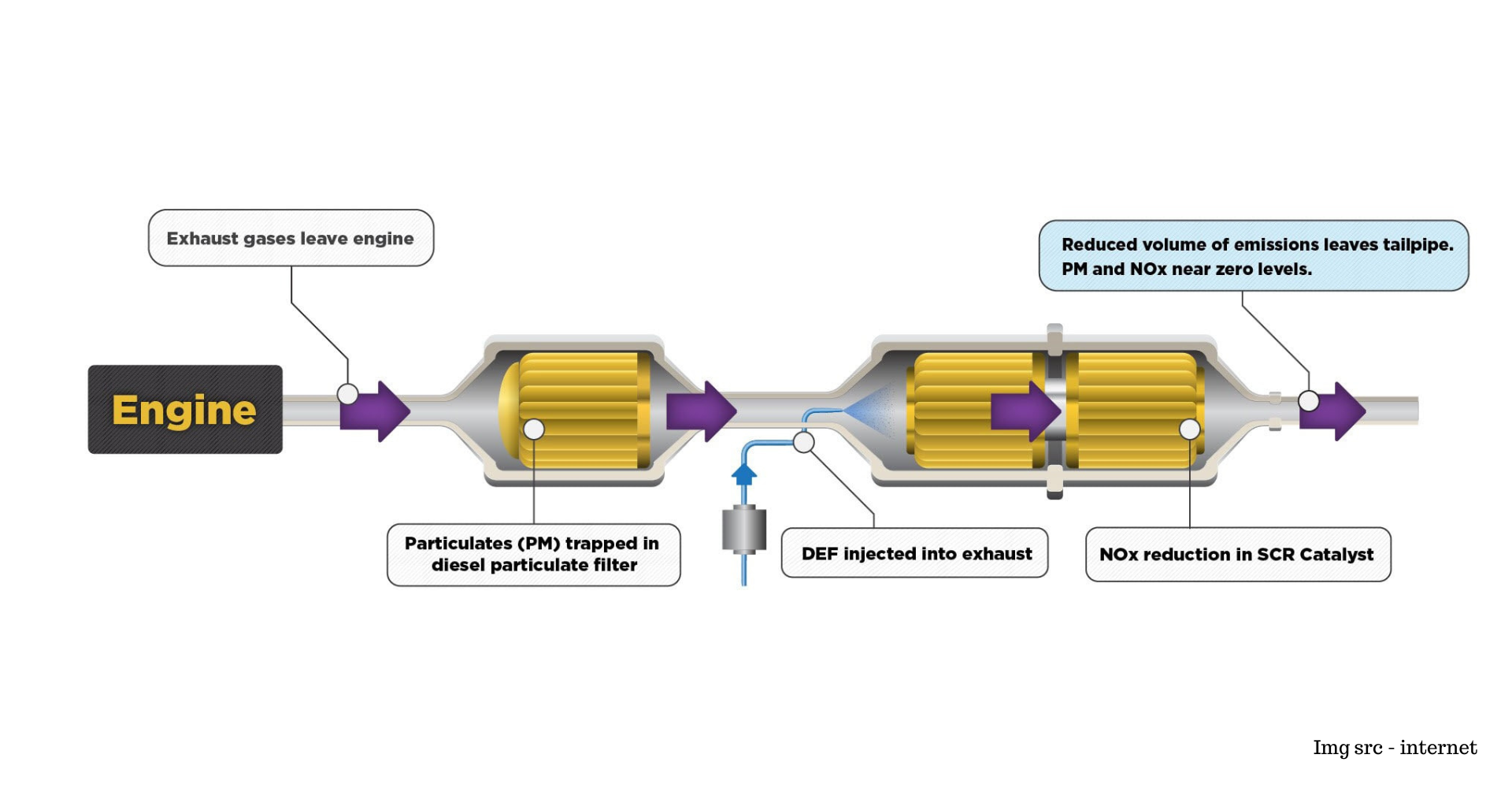

The SCR system is located in the exhaust stream of the engine, where it catalyzes the breakdown of NOx into harmless nitrogen (N2) and water vapor (H2O). The process begins when AdBlue is injected into the exhaust gases. As the hot exhaust gases mix with AdBlue, the urea in AdBlue decomposes into ammonia (NH3) and carbon dioxide (CO2). This decomposition occurs at high temperatures, typically above 200°C, which are standard in diesel engine exhausts.

The ammonia produced is the key agent in the reduction of NOx. As the exhaust gases, now containing ammonia, pass through the SCR catalyst, a reaction occurs that converts the NOx into nitrogen and water. This reaction is highly efficient, reducing NOx emissions by up to 90% in some cases. The nitrogen and water vapor produced are naturally occurring and harmless, significantly reducing the environmental impact of diesel engines.

The Role of SCR and AdBlue in Modern Diesel Engines

The integration of SCR and AdBlue in diesel engines is not just about compliance with environmental regulations; it’s also about improving engine performance and efficiency. SCR systems allow engines to operate at higher temperatures and pressures, which improves fuel efficiency and reduces particulate matter emissions. This dual benefit—lower NOx emissions and improved fuel efficiency—makes SCR and AdBlue a powerful combination in the fight against air pollution.

One of the critical aspects of SCR systems is that they are designed to operate with a specific concentration of urea, which is why the 32.5% concentration in AdBlue is so important. This precise formulation ensures that the decomposition process is optimized, and the maximum amount of NOx is converted into harmless gases. Any deviation from this concentration could result in incomplete reactions, leading to higher NOx emissions and potential damage to the SCR system.

Challenges and Considerations

While AdBlue is a critical component in reducing emissions, its effectiveness depends on proper usage and maintenance. For instance, the storage and handling of AdBlue are crucial to maintaining its quality. AdBlue should be stored in a cool, dry place, away from direct sunlight and extreme temperatures. Contamination of AdBlue can impair the SCR system’s performance, leading to increased emissions and potential engine issues.

Additionally, the consumption rate of AdBlue varies depending on the vehicle type, driving conditions, and the specific SCR system used. On average, AdBlue consumption is about 2-6% of diesel fuel consumption, meaning that for every 100 liters of diesel fuel used, approximately 2 to 6 liters of AdBlue are required. Vehicle operators must regularly monitor and refill the AdBlue tank to ensure continuous compliance with emissions standards.

The Future of Emissions Control

As emissions standards continue to evolve, the role of AdBlue and SCR technology is likely to expand. Innovations in this area are focused on enhancing the efficiency of NOx reduction and improving the overall performance of diesel engines. For instance, advanced sensors and control systems are being developed to optimize the injection of AdBlue, ensuring that just the right amount is used to achieve maximum emissions reduction without wasting the fluid.

Moreover, as hybrid and fully electric vehicles become more prevalent, the demand for technologies that clean up traditional internal combustion engines will remain strong, especially in sectors like freight and heavy industry where diesel engines are still dominant. AdBlue, therefore, will continue to play a vital role in the transition to cleaner transportation and industrial practices.